International technology group ANDRITZ has developed the PrimeDry HotAir Box, an innovative solution that enables tissue producers to reduce energy consumption and CO₂ emissions while increasing machine efficiency.

Designed to address the energy-intensive nature of tissue drying, the PrimeDry HotAir Box recovers a portion of the hot, wet exhaust air from the drying hood for reuse in the process.

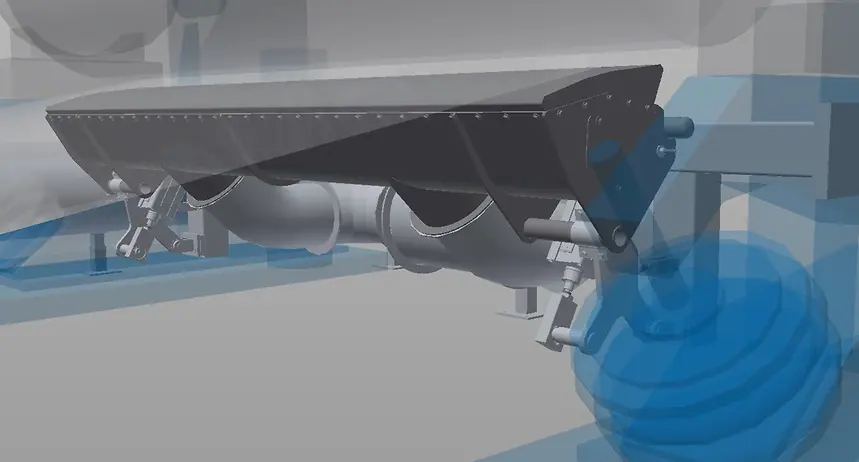

The exhaust air is separated after the air-to-air heat exchanger, filtered, and evenly blown onto the tissue web ahead of the suction roll. The temperature increase reduces the water viscosity of the web, resulting in higher dryness after the press. In this way, the PrimeDry HotAir Box contributes to a significant reduction in the total energy required to achieve the final paper dryness or to a significant increase in production.

The PrimeDryHotAir Box includes a retraction system allowing for maintenance, tail threading and cleaning operations. The filter is cleaned automatically at regular intervals.

Compatible with any suction press configuration, the system is suitable for new installations and rebuilds.