International technology group ANDRITZ has introduced a new type of drying hood with electric heating that helps tissue machine operators replace fossil fuel, thus avoiding carbon emissions and progressing towards their sustainability goals. In addition, the system offers increases in energy efficiency and production rates compared to conventional fossil-fueled systems. An order was already placed, start-up will be by the end of this year.

“We developed the new hood in close cooperation with customers. It perfectly matches today’s need for sustainable and especially CO2 reduced high-quality tissue production. Having received the first order right after the market launch is the best proof that we are meeting our customers’ needs,” says George Nowakowski, Vice President Tissue Drying, ANDRITZ Canada.

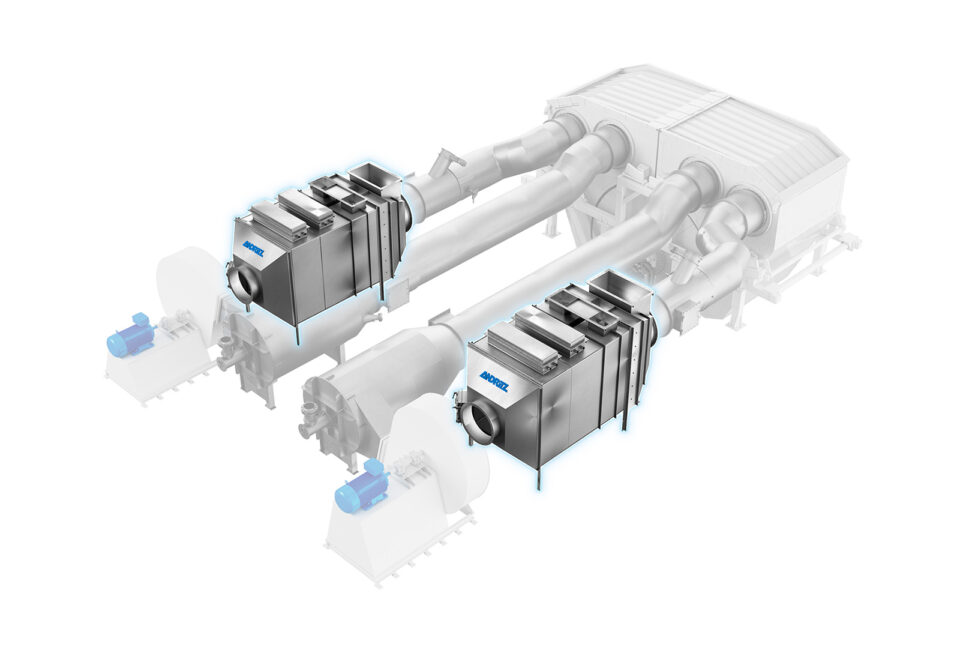

The ANDRITZ PrimeDry Hood E uses electric heating elements to heat the air flows in the hood. As a result, carbon emissions from tissue machines can be reduced by about 70% from conventional gas-heated systems. As the new hood does not require any combustion air, energy efficiency for the drying system increases by up to 4% compared to gas-heated systems. With its ability to achieve air temperatures of up to 450°C, it can contribute to higher production compared to steam-heated systems.

To allow for more flexibility, the PrimeDry Hood E is also available as a hybrid model, with an air system that combines electric air heating elements with natural gas burners working in tandem arrangements. This enables customers to select the most favorable mode of heating considering changes in energy prices and energy sources available.

ANDRITZ offers products and services for the entire tissue production process, from fiber preparation to the tissue machine, including fabrics and rolls, pumps, automation and services designed to help reduce environmental impact without compromising end-product quality.